Why Choose Us

Industrial Manufacturing

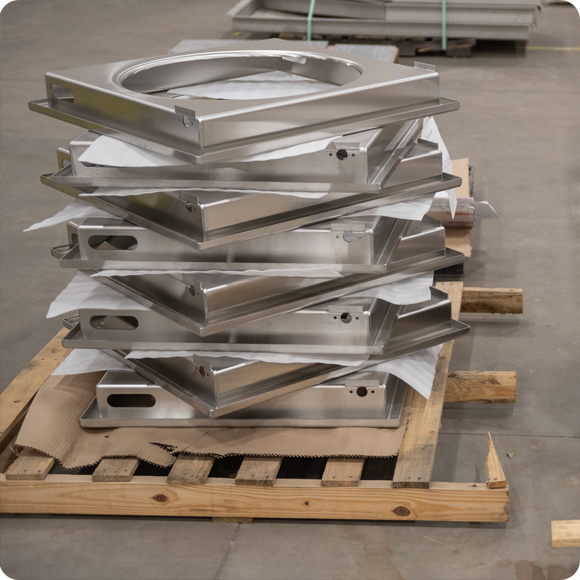

Our Industrial Manufacturing business unit makes it easy to source high-quality mid- to high-volume production runs of repeatable parts.

We’d love to be your contract manufacturing partner and deliver the expertly crafted parts you need. Whether you’re looking for a comprehensive stocking program or a straightforward run of fabricated components, the Industrial Manufacturing business unit of Industrial Works is the partner for you.

Contract Manufacturing of Metal Fabricated Parts

Leverage a partnership with Industrial Works to fabricate your parts! After determining the scope and scale of your project, we can set up a consistent production of the parts you need.

We streamline the production of your parts and consistently deliver on the quotas we agree upon.

Our in-house quality team ensures every single part stands up to our rigorous standards. Whether it’s part two or part two thousand, we’ll deliver you a consistent, high-quality product.

Quick-Ship Programs

We can assist our customers with stocking programs tailored to their needs. By maintaining a consistent inventory of ready-to-go parts, you’ll never have to worry about supply bottlenecks affecting your production.

Using KanBan-style stocks based off of your estimated annual usage, we can ensure you’ll always have enough parts. It’s just another way the Industrial Works team goes above and beyond to maintain our customers’ satisfaction.

Non-Reoccurring Engineering (NRE)

We don’t just manufacture your parts – we make them in the most efficient way with the highest level of quality and savings possible. Our cutting-edge technology helps drive consistent quality and repeatability in your parts.

By taking a critical look at the product development stage, we can help achieve more consistent results that lead to long-term success. From engineering through manufacturing, our IMFG team ensures your fabricated parts live up to your exact specifications.

Set your parts run up for success and take it to the Industrial Manufacturing unit at Industrial Works! We would love to tell you about our specific capabilities, so reach out to us today.